1. Introduction: Why Board Feet Matter in Spray Foam Projects

After working with contractors and homeowners on spray foam installations for over a decade, one issue appears more than any other: material miscalculation. Ordering too little foam stops the job halfway. Ordering too much inflates your budget unnecessarily.

That’s why understanding board foot calculations is essential. In fact, almost every major manufacturer—like Tiger Foam, Foam It Green, and Touch ’n Foam—prices their spray foam in board feet, not gallons or pounds.

A proper board foot estimate ensures:

- You won’t run out of product mid-project

- You’ll apply the correct thickness for the desired R-value

- You’ll avoid overspending on excess material

According to the U.S. Department of Energy (DOE), proper insulation thickness is critical to achieving expected energy savings—sometimes up to 20% annually. Therefore, getting board foot calculations right directly impacts performance and long-term efficiency.

Related Calculator

Spray Foam Insulation Cost Calculator

Spray Foam Insulation Cost Calculator | Estimate Your Project Spray Foam Insulation Cost Calculator Estimate your spray foam insulation project…

Use This Calculator📁 More Construction Calculators

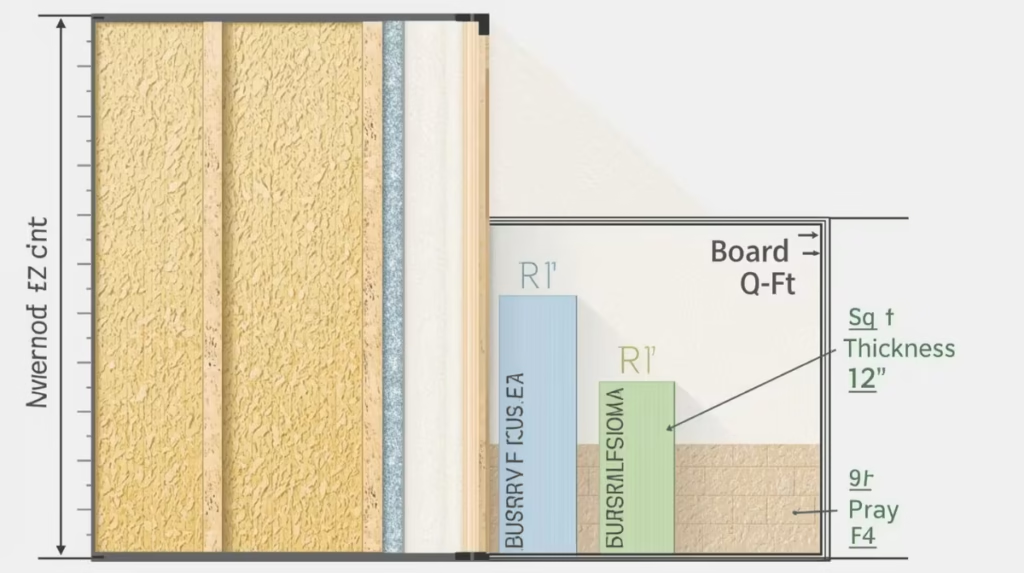

🔍 Explore All Construction Calculators2. What Is a Board Foot? (Simple Definition)

A board foot is a standardized measurement used across the insulation and lumber industries.

Simple Definition:

1 board foot = 12 inches × 12 inches × 1 inch thickness

This unit makes it easy to sell and estimate spray foam because:

- Foam expands

- Thickness varies

- Coverage depends on R-value requirements

Why Foam Is Sold This Way

Because both open-cell and closed-cell foam expand to different thicknesses, selling insulation by board foot creates a uniform metric for coverage.

Thickness Directly Affects Coverage

Example:

- A kit labeled 600 board feet will cover:

- 600 sq ft at 1 inch thick

- 300 sq ft at 2 inches thick

- 150 sq ft at 4 inches thick

3. How to Calculate Board Feet for Spray Foam (With Examples)

Here’s the formula almost every contractor uses:

Board Foot Formula:

Square Feet × Thickness (in inches) ÷ 12 = Board Feet Needed

Let’s walk through real examples:

Example 1: Attic Area

- Area: 500 sq ft

- Thickness: 2 inches

500 × 2 ÷ 12 = 83.33 board feet

Multiply by 10 or 12 for full-coverage kits depending on expansion.

Example 2: Garage Wall

- Area: 240 sq ft

- Thickness: 3 inches

240 × 3 ÷ 12 = 60 board feet

Coverage Chart (Quick Reference)

| Board Foot Kit Size | 1″ Coverage | 2″ Coverage | 3″ Coverage |

| 200 board feet | 200 sq ft | 100 sq ft | 66 sq ft |

| 600 board feet | 600 sq ft | 300 sq ft | 200 sq ft |

| 1200 board feet | 1200 sq ft | 600 sq ft | 400 sq ft |

This is why knowing board feet saves time and money—it makes purchasing accurate.

4. Closed Cell vs Open Cell: Board Foot Differences

Density

- Closed cell: ~2 lb density

- Open cell: ~0.5 lb density

R-Value

- Closed cell: R-6 to R-7 per inch

- Open cell: R-3.5 per inch

Closed cell requires fewer inches to reach the same R-value.

Cost per Board Foot

- Closed cell: $1.00–$1.50 per board foot

- Open cell: $0.45–$0.65 per board foot

Closed-cell foam costs more but performs significantly better for air sealing, moisture resistance, and structural strength.

5. Tools & Calculators for Board Foot Measurement

If you don’t want to calculate manually, use the tools that pros trust.

Top Online Board Foot Calculators

- SprayFoam.com Board Foot Calculator

Industry standard; widely used by contractors - Foam It Green Coverage Calculator

Great for DIY estimation - Tiger Foam Board Foot Tool

Provides kit recommendations - Home Depot R-Value & Coverage Estimator

Good for basic home projects - Energy.gov Insulation Estimator

Highly reliable and data-driven

Mobile Apps

- Construction Master Pro

- CalcPro

- Spray Foam Calculator Pro

Contractor Software

- JobNimbus

- AccuLynx

- BuilderTrend

These tools are accurate and reduce measurement mistakes significantly.

6. Common Mistakes to Avoid When Calculating Coverage

Even experienced installers make errors. Avoid these:

1. Not Converting Inches to Board Feet Correctly

Always divide thickness (in inches) by 12.

2. Underestimating Voids

Gaps, beams, and angled surfaces change actual square footage.

3. Ignoring Foam Expansion

Each foam brand expands differently—always check the manufacturer’s chart.

4. Assuming Both Foam Types Cover Equally

Open-cell expands more than closed-cell.

5. Forgetting Overspray Waste

Account for 10–15% extra material for most projects.

7. Final Tips for DIY and Professionals

When You Need a 200 Board Foot Kit

Best for:

- Small walls

- Rim joists

- Crawl space patches

- Single rooms

Choosing DIY Kits

Look for:

- Minimum 600 board foot kits for larger areas

- Kits with fan spray nozzles

- Temperature-controlled hoses

Use a Thickness Chart

Each manufacturer provides a recommended R-value thickness chart—for example:

- Closed cell: 2″ = R-12, 3″ = R-18

- Open cell: 3.5″ = R-13, 5.5″ = R-19

Thickness determines energy efficiency, comfort, and cost.

FAQs

1. How many board feet do I need for 1,000 sq ft?

At 1 inch thick: 1,000 board feet.

At 2 inches thick: 2,000 board feet.

2. Is closed-cell spray foam worth the extra cost?

Yes—its higher R-value and moisture resistance make it ideal for attics, basements, and garages.

3. Can I measure board feet without a calculator?

Yes—use the formula: sq ft × thickness ÷ 12.

4. What does a 600 board foot kit cover?

600 sq ft at 1 inch OR 300 sq ft at 2 inches.